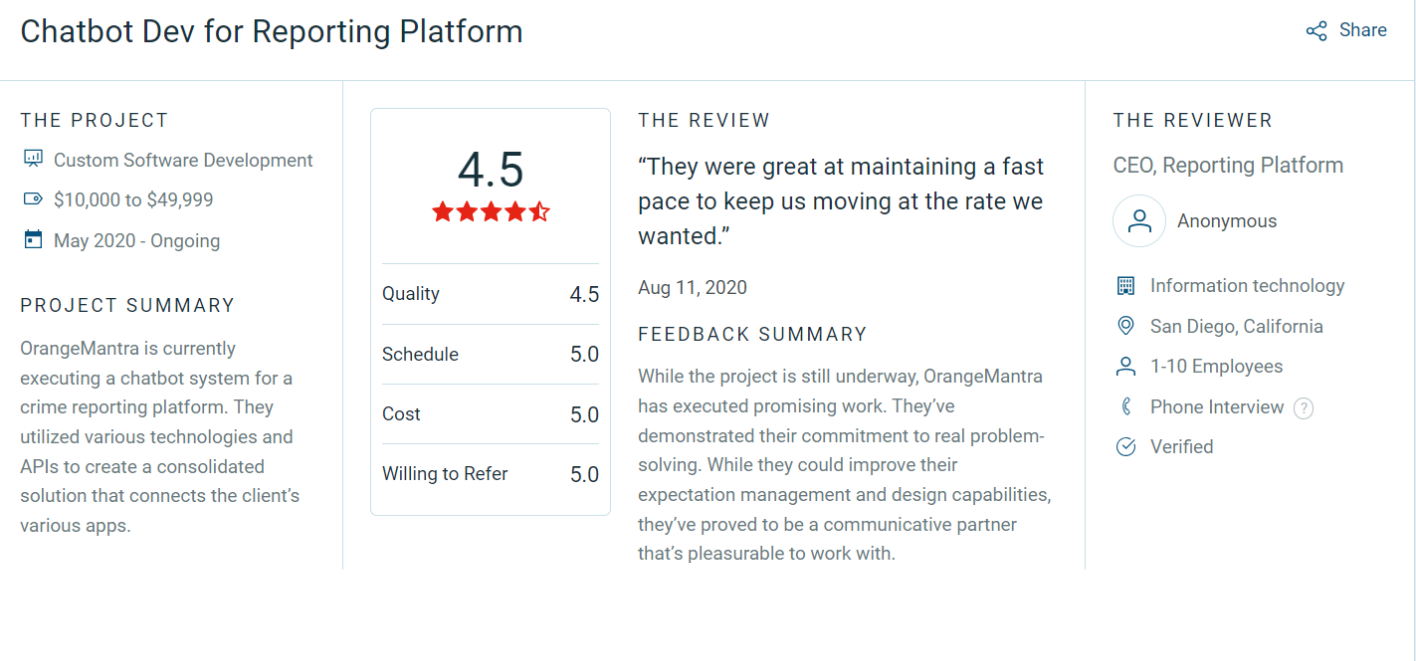

Our client is a manufacturer well-known for their affordable, personalized, and durable car spare parts. They have a strong presence in UK manufacturing hub. However, the sales number were reducing at an exponential rate due to the COVID-19 crisis. Moreover, the high volume of data collection proved a severe challenge to predict the sales number. Furthermore, the complex situation ended in market demand fluctuating at a rapid pace, the client therefore could not forecast necessary stock quantities and the sales number continued to reduce. The client reached to OrangeMantra for an AI-powered solution for sales prediction and revenue generation.

Manufacturing

AI/IoT/Emerging Tech

OrangeMantra team built and implemented a AI prediction model based on the historical data, market behavior factors, and other 3rd party data. The model predicts demand and next calculates the optimal prices for the sellers. The solution automatically forecasts monthly and weekly sales, based on the demand and supply analysis, an optimal price is chosen.

Our team started with collection of historical sales data, customer information, and market trends. Used tools to refine and process the data to keep quality and consistency intact.

Build a machine learning model with the support of regression algorithms and time-series methodology. The model is trained on historical data for ensuring accurate predictions.

The AI model is integrated with the existing Enterprise Resource Planning (ERP) for streamlined flow data across the funnel. Real-time updates and synchronization of data between departments was the core objective.

The presence of AI model helped in prediction of future demands and optimize inventory levels. Implemented automated restocking recommendations for resolving out-of-stock and overselling.

Sales and revenue forecasting is not simple job and needs to focus on imitating trends. Analyzing a large volume of data comprising customer behavior patterns, preferences, and future trends and drawing final conclusions. OrangeMantra has developed an AI application that is able to predict market demand and order quantity with high accuracy, based on order history, old records and product information.

The initial challenge was to overcome resistance from employees who are new to AI technology and anxious about its integration into the sales and revenue generation method.

Another challenge was to keep the costs associated with AI implementation intact, including development, training, and maintenance, and allocating resources in an effective way.

AI-based solutions enable client to forecast demands based on target groups’ shopping behaviors while keeping a check on the seasonal trends. Based on the data forecasts, the application allows managers to avoid costly delays while simultaneously lowering the work they need to perform. This sales prediction case study shows how with improved accuracy using AI, the client optimize the usage of resources. Moreover, operational costs were reduced while keeping up with their client’s demands.

The dynamic pricing approach resulted into increased revenue. AI helped to adapt prices in response to market dynamics, competitors, and customer demands.

The client experienced reduced manual workload with the automation of sales prediction, inventory management, and pricing strategies helping to focus on critical jobs.

The manufacturing giant gained real-time insights into latest market trends and customer behavior, helping in making proactive decisions and strategic plans.