Expert AI-Driven Manufacturing Solutions Setting Standards

AI Powered Live Production Monitoring

We deliver insights so that you can improve the product quality and keep the production process running smoothly with AI powered systems. Clearing out bottlenecks with the power of big data analytics and computer vision.

Advanced Product Scheduling with AI

AI has got your production schedule covered. The AI powered systems have ML and Predictive analysis that can improve AI algorithms to adjust production schedules in real time. With Cloud computing and IoT you will not have to deal with any more delays and stay focused on growth.

Quality Control Assurance

Detect defects with high precision through manufacturing AI Agents that includes computer vision, machine learning along with deep learning algorithms. Additionally edge computing and cloud integration allows only the top-quality products to make it off the production line, that reduces waste.

Supply Chian Risk Management

Forsee and eliminate risks with not just one manufacturing AI agent but many. We make use of predictive analytics, machine learning, big data, cloud computing and additionally now consider IoT to track real time data from various supply chain touchpoints. It goes beyond just a single solution.

Intelligent Energy Management for Sustainable Manufacturing

Using a broader range of solutions, we maximize energy efficiency by integrating AI, IoT, and analytics so that operations can consume energy smartly. These cuts cost and waste while supporting your green manufacturing goals.

Revolutionizing Assembly Lines with AI Automation

Get rid of repetitive tasks and optimize assembly lines when RPA, computer vision, and IoT sensors that significantly reduces human error and accelerates production cycles keeping also the operational cost low well.

Quality Assurance with AI

Automating quality control to spot discrepancies. With Image recognition and AOI you will find flawless production every time.

Smart Warehouse Automation

With AI and Robotics on the job, transform warehouse operations. We provide automated inventory management to efficient order picking and storage, our AI-powered systems are backed by vision sensors and robotics, keep stock levels perfectly in sync with demand.

AI-Based Supplier Performance Analysis

Analyzing delivery time, quality of raw materials, and cost efficiency with AI manufacturing agents that offer insights to manufacturers. Selecting the best-performing suppliers with the help of these insights gets easier now and there is consistent quality timeliness of the raw material supply chain.

AI Takes the Wheel in Smart Manufacturing

AI is everywhere and the manufacturing industry is heavily reliant on it as they are seeking rapid advancements. With changing times, AI manufacturing agents are setting new standards as businesses are able to make accurate decisions with their cutting-edge solutions.

Intelligent Process Automation

Smart Energy Management

Real-Time Data Insights

Autonomous Production Lines

- 100%

Client Satisfaction

- 90%

Increased ROI

- 500+

Global Clients

Our Custom AI-Powered Manufacturing Solutions for Success

At OrangeMantra, our end-to-end security services for automotive businesses are tailored specifically to your requirements, use cases, budget, and pain points.

AI in Manufacturing: From Vision to Reality

Pharmaceutical Assembly Lines with AI Automation Our client, a pharmaceutical manufacturer, was having a hard time dealing with slow production cycles and manual errors in assembly. But we stepped in to provide them with AI driven automation solutions that streamlined assembly lines and reduced manual tasks that improved production precision. The result was that production time was cut down by 40% and improved efficiency by 30% therefore eliminating all human errors on the assembly line.

View Case Study

Energy Efficiency Redefined A sustainable manufacturing company struggled with energy inefficiency and skyrocketing costs. With our AI-powered energy optimization solution, we tracked real-time energy usage and adjusted consumption on the fly. This led to a 25% reduction in energy costs, significantly minimized energy waste, and helped them achieve their green manufacturing goals.

View Case Study

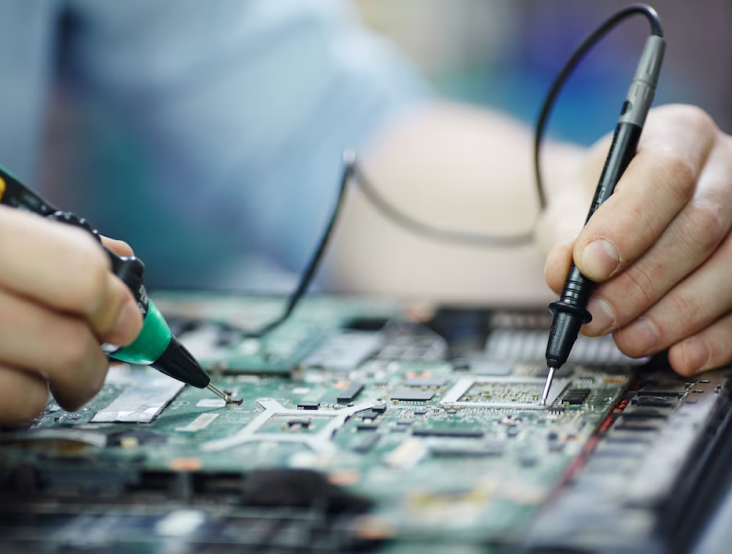

Quality Control in Electronics Manufacturing An Electronics Manufacturing Leader, our client encountered difficulties with a high defect rate and unpredictable product quality. To tackle this, we implemented AI-based real-time monitoring and defect detection systems, utilizing machine learning and computer vision. The result? Product quality improved by 20%, defect rates dropped by 35%, and customer satisfaction soared, significantly enhancing their overall production process.

View Case Study

Our Reputable Clients

Our Tech Stack for the Best AI-Powered Manufacturing Solutions

-

Programming Languages

-

Python

-

C++

-

Java

-

R

-

MATLAB

-

Frameworks

TensorFlow

Keras

PyTorch

OpenCV

Scikit-learn

-

Tools

Docker

Kubernetes

PostgreSQL

Jenkins

Tableau

-

Software & Platforms

AWS

Google Cloud

Microsoft Azure

-

IBM Watson

SAP

Smart Manufacturing Starts with AI Agents by OrangeMantra

AI agents that automate tasks, optimize workflows, and reduce downtime we help you lead the way.

Let’s Partner-

15+

Industries Revolutionized

-

2000+

Hours Saved with Automation

200+Manufacturing Solutions Implemented

23+Years of experience

Hear From Our Clients

“OrangeMantra’s AI agents didn’t just improve our manufacturing but had turbocharged it! With smart automation and real-time insights, workflows were optimized, downtime vanished, and costs took a 25% dive. Efficiency? Off the charts!

- Sunil

“We have gained real-time insights that improved our decision-making. Our entire production workflow is now optimized and more reliable.”

- Rahul

“We have seen significant improvements in productivity. Thanks to OrangeMantra and their use of IoT-enabled smart devices, our manufacturing line is more agile than ever. Real-time data and connected systems have optimized our workflow, showed more quicker operations.

- Divyanshu

Python

Python

C++

C++

Java

Java

R

R

MATLAB

MATLAB

TensorFlow

TensorFlow  Keras

Keras  PyTorch

PyTorch  OpenCV

OpenCV  Scikit-learn

Scikit-learn  Docker

Docker Kubernetes

Kubernetes  PostgreSQL

PostgreSQL  Jenkins

Jenkins  Tableau

Tableau  AWS

AWS  Google Cloud

Google Cloud  Microsoft Azure

Microsoft Azure IBM Watson

IBM Watson  SAP

SAP