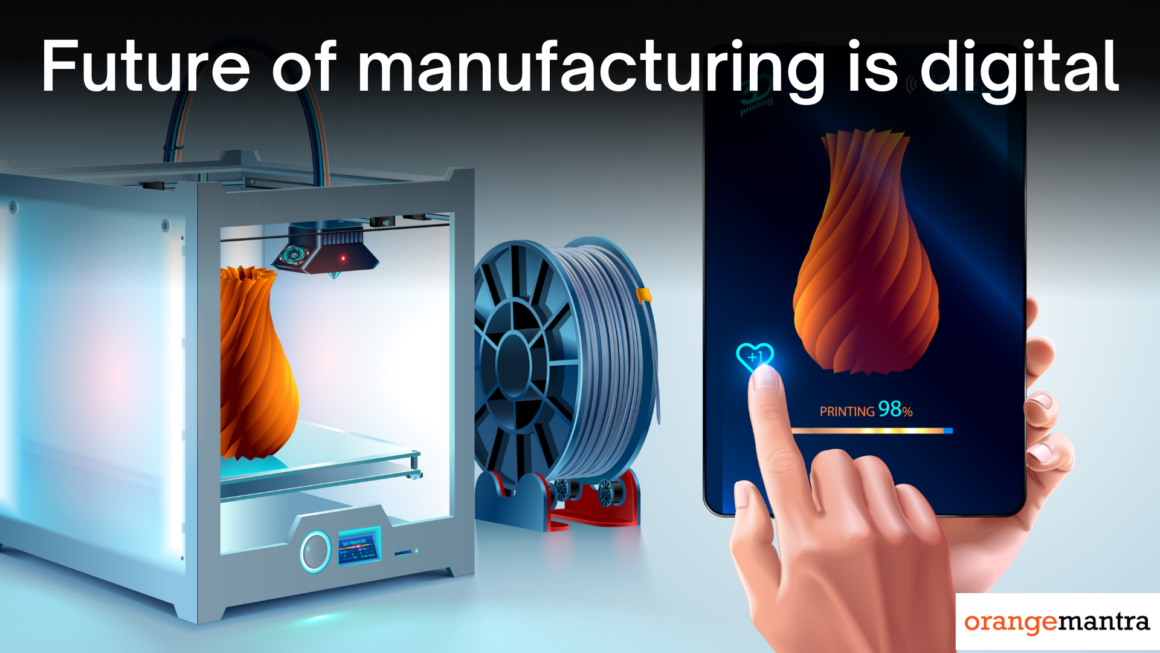

As the buzz around digital manufacturing swept industries, 3-D manufacturing companies saw a much-desired boost in 2020. It’s partly because some top healthcare companies raced to overcome the medical supply shortage. Over a year into the pandemic, and yet the digital manufacturing buzz has not subsided. And 3-D printing companies continue to benefit. One such company is Formlabs. The Massachusetts-based 3-D printer raised $150 million in funding led by SoftBank, The Wall Street Journal reported.

3-D printing companies continued to experience significant growth driven by a bullish prediction early in 2021. By February, the top 4 publicly traded companies saw their stocks quadruple. Shares of industry pioneers 3D Systems and ExOne were up more than 570%, according to a WSJ report.

Is 3-D Printing Going Mainstream?

Not so fast. But, evidently, corporate interest in new digital manufacturing methods is rising, said Michael Shanler, the distinguished analyst at the technology research firm, Gartner. It’s partly because business leaders accelerated technology adoption amid the pandemic. For instance, the number of companies deploying healthcare solutions reached record levels.

“Organizations have put in the effort to figure out what manufacturing of the future should look like,” said Shanler, the Gartner analyst. When the pandemic was at its peak in the U.S. last year, large companies and startups alike either deployed or reprogrammed their 3-D printers to deal with medical supply shortages. For example, the Northwell Health hospital system used Formlabs printers to make nasal swabs, as demands for PPE soared.

However, 3-D printing is yet to reach mass-market industrial adoption for manufacturing. Analysts say limitations on the types of the device compatible with 3D printing is a major roadblock. Besides, sometimes there are defects in the printed objects, raising quality issues. Factors like these continue to slow the pace of adopting digital manufacturing. But companies are finding tech-enabled strategies to overcome these challenges.

Prototyping for 3-D Manufacturing

A growing number of companies now use cutting-edge technology to experiment with 3-D printing. Building prototypes is now a dominant trend in the 3-D printing industry. For manufacturing startups, 3-D printing solutions provide a tool for entering the market quickly. For instance, the California-based company Glidewell Dental used Formlabs printers to produce tens of thousands of nasal swabs and components for medical masks. It not just enabled the company to meet soaring demands amid the pandemic but also helped recover business losses.

Formlabs’ Remarkable Growth

Formlabs usually strike 3-D printing deals with CIOs, CTOs, and other corporate execs. The company’s 3-D printers enable customers to print digital objects as diverse as jewelry and dental retainers. Formlabs printers use nearly 30 different plastic materials. It also builds the software required to operate the company’s three product lines. Like all other areas of the business world, enterprise software solutions play a critical role in digital manufacturing, as well.

Formlabs said the company will use the new funding to hire more staff for its engineering, sales, marketing, and finance teams. It also plans to accelerate product development and expand further internationally, said Max Lobovsky, chief executive and co-founder of Formlabs.

A Digital-driven Future of Manufacturing

More and more companies across industries are using 3-D printing to build production parts instead of prototype parts. “We are standing at the inflection point of unprecedented growth in the way products are being made,” said Deep Nishar, senior managing partner at SoftBank Investment Advisers. Companies like Formlabs are continually improving the quality of 3-D printing. With the pandemic having unprecedented impacts on manufacturing, industry execs are more open to embracing technologies like automation and 3-D printing. Analysts say the current buzz around digital manufacturing will only swell in the coming years.