Warehouses are the integral element of every supply chain model. They are hubs to store, organize, and distribute goods to the right audience. However, traditional warehouse management solutions are not optimized to serve the modern business needs. They lead to numerous challenges for business groups, including:

- Manual tracking results into discrepancies in inventory records, stockouts or overstock situations for buyers.

- Paper-based inventory and manual workflows reduce efficiency, ending into bottlenecks and business

- Limited access of inventory movements and delays in order status can impact brand decision-making

- With the high demand of eCommerce operations, it is important to deliver products at a faster rate with features of real-time order tracking. This has put business groups under extreme pressure to operate with fast-paced

To address these challenges, smart warehouse management system has become a mandatory addition in competitive and demanding business world. In this blog, we will discuss how smart warehouse is bringing desired results for brands.

Introduction to Smart Warehouse Management System

Smart warehouse management system is integrated with latest technologies bringing automation to mundane and repetitive jobs of manual entry and traditional work process. The system leverages a combination of next-gen tools and technologies, consisting of IoT sensors, RFID tags, AI, and data analytics. All constitute towards the common goal of optimizing every aspect of warehouse operations.

- IoT sensors and RFID tags helps with the real-time tracking and monitoring of products, and equipment. Thisprovide unparalleled and real-time access of the warehouse activities.

- AI algorithms and machine learning is an integral part of intelligent warehouse management system to optimize processes, forecast demand patterns, and ensure overall efficiency is improve

- Data analytics dashboards and reporting tools helps warehouse team to make informed decisions withactionable insights.

- Moreover, smart solution help in seamless integration with other systemsincluding ERP software and fleet management. This is a great addition for seamless data flow across the whole supply chain.

Importance of Adopting Technology in Warehouse Operations

To stay ahead of competition in today’s fast-paced business environment, technology is an important asset. It is a necessity for warehouses to meet complex and challenging inventory management, order processing, stock update process. By embracing smart warehouse management system, you can reap multiple benefits, including:

- Technology provides automation of mundane tasks, workflow optimization, and real-time monitoring for faster processing and improved

- Data collection process has become automated and inventory tracking is free from errors and discrepancies. This has proved inventory accuracy and reduced the risk of out of stock and overstock situations.

- Warehouse have become more productive in meeting customer diverse requirements. Faster order processing, accurate order, and real-time visibility are some of the advantages of having emerging tech solutions for your brand.

- Streamlined processes, secure inventory updates, and reduced operational costs result in improved profitability when operating cost is too high.

- Smart warehouse management system is designed to serve changing business needs and technological You will experience agile and responsive outcome in the face of change.

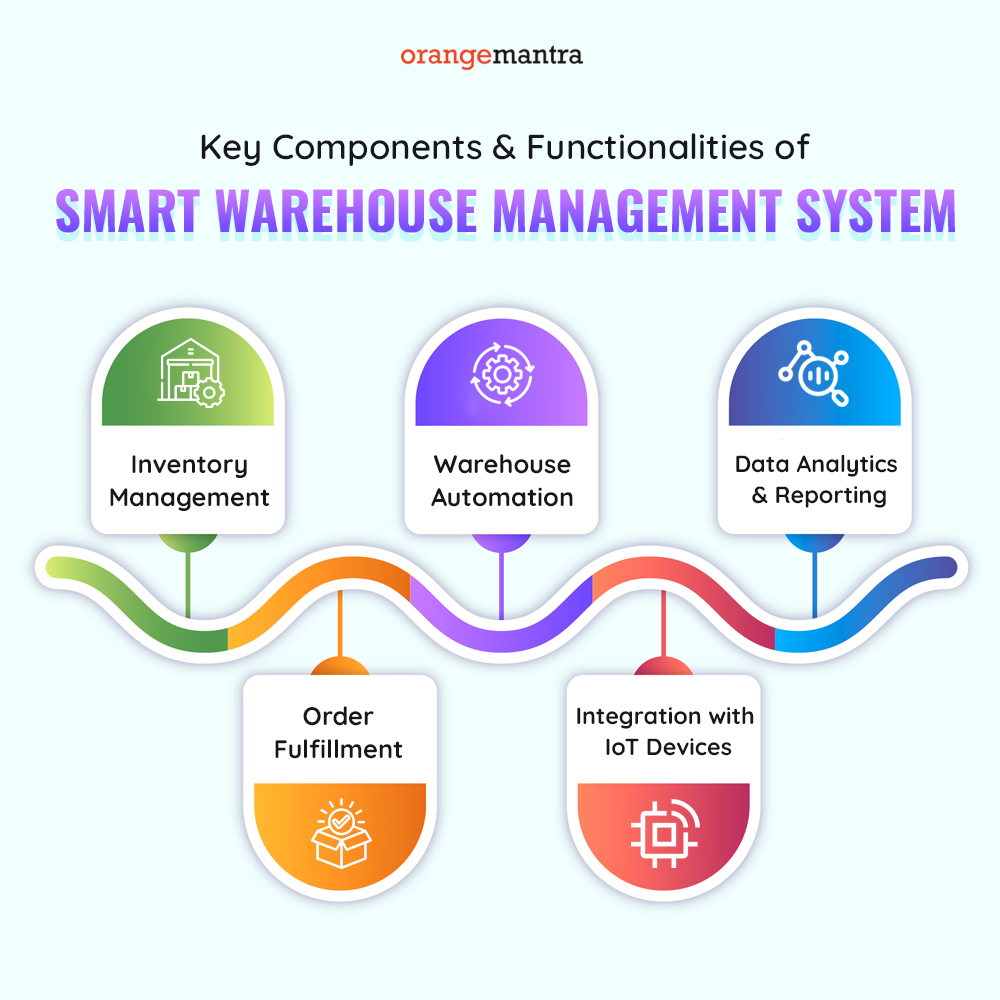

Key Components and Functionalities of Smart Warehouse Management System

Smart warehouse represents a solution that integrates next-gen technologies to optimize every phase of supply chain operations. Warehouses can improve efficiency, accuracy, and responsiveness, for profitability and business growth.

Inventory Management

- Smart warehouse system is supported by IoT sensors, RFID tags, and barcode to keep a track of inventory in real time. This ensures warehouse team to have information about stock levels, location, and status of each

- AI is used to analyze data, demand forecasts, and other crucial information to optimize inventory levels. This eliminates the situation of stockouts, overstock, and transportation

- Reaching to an AI development company build solution to get insights regarding demand patterns, anticipate future demand and build inventory plan.

Order Fulfillment

- Smart warehouse management system automates order workflows. It comprise of receipt to picking, packing, and delivery to end user. This eliminates the possibility of manual errors, track order, and personalize customer services.

- AI-powered algorithms helps to reduce delivery time by selecting shortest delivery route. This is an efficient method of allocating warehouse resources and improves

- Smart software helps warehouses to lower operational and transportation costs by optimizing delivery route when multiple fulfillment centers or distribution routes are present.

Warehouse Automation

- Merging warehouse software with robotic systems automate repetitive tasks such as material handling, sorting. The technique involves automated guided vehicles (AGVs), robotic arms, and automated picking systems. This is a perfect way for your business to improve operational efficiency, lower labor costs, and improve staff

- Automated conveyor streamline flow of goods between different areas of the warehousein secure manner. It reduce manual handling and even improve productivity based on demand and inventory levels.

- Presence of automated storage and retrieval process maximized storage usage and efficiency. Smart software helps with inventory allocation to keep a check on the space utilization.

Integration with IoT Devices

- IoT sensors have completely transformed the way of collecting data on different parameters including temperature, humidity, and other environmental factors. They are majorly embedded in warehouse equipment, and shelves. You can use data for creatingoptimal storage conditions, identify anomalies, and avoid product damage or spoilage.

- RFID tags enable automatic identification and tracking of product when they move from one location to another in the warehouse. Smart warehouse management system with RFID functionality capture and update inventory in real time for accurate results.

- Wearable devices are also powered by IoT sensors helping with barcode scanners, smart glasses, and wrist-mounted terminals. These devices provide real-time access to information and given Merging these wearable devices with your smart warehouse system optimize tasks like inventory update, stock records, and quality control.

Data Analytics and Reporting

- Smart warehouse system is designed to keep a check and process data collected from multiple sources, including IoT devices, ERP, CRM and warehouse management systems (WMS). AI-driven generate actionable insights to make informed decisions for operational performance, customer behavior and inventory trends.

- Dashboards share timely reports with the warehouse managers offering real-time visibility within the key performance indicators (KPIs). Major KPIs to consider are order fulfillment rates, inventory records, staff productivity, and equipment utilization. This improves decision-making process and ensure continuous improvement.

- For prediction of stock risks, possible bottlenecks, you can consult Machine learning development company to integrate with your warehouse software. ML helps to anticipate future trends and issues, smart software aids warehouses to proactively address challenges and ensure resource allocation.

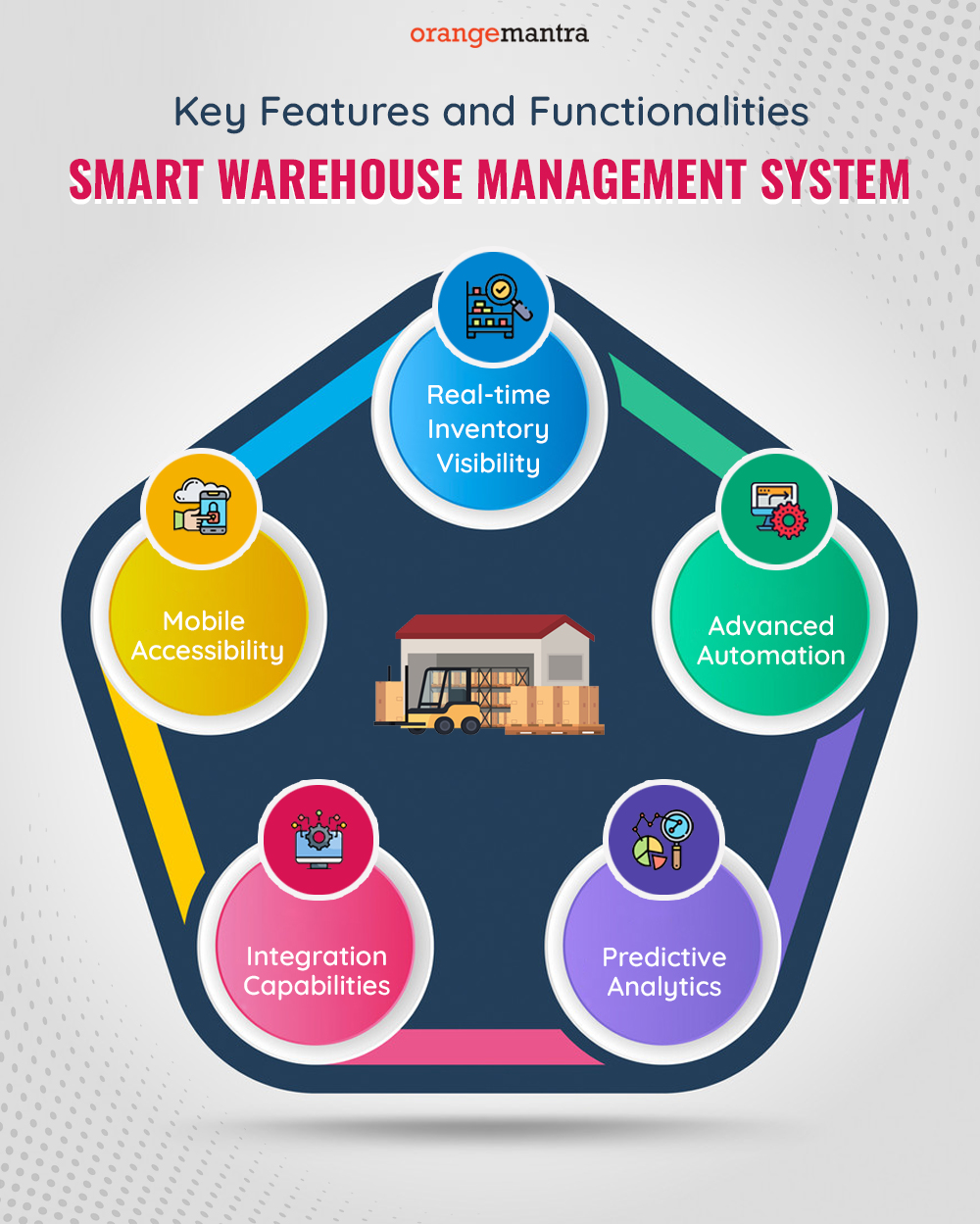

Key Features and Functionalities of Smart Warehouse Management System

Real-time Inventory Visibility

Leveraging services of the smart warehouse system provide real-time visibility within the inventory records, locations, and product movements. Renowned features like RFID tagging, IoT sensors and barcode scanning, enable accurate and real-time inventory items tracking.

Advanced Automation

Automation is useful to simplify and fasten repetitive jobs of order picking, packing, and sorting. This reduce manual labor and even improves efficiency. Automated guided vehicles (AGVs), conveyor systems and robotic arms are game changer for warehouse setup to automate overall handling processes.

Predictive Analytics

Predictive analytics feature of Smart warehouse helps to forecast demand patterns, anticipate inventory requirements, and eliminate future issues. ML analyze collected data and external factors for real-time sharing of actionable insights to make result-oriented decision-making.

Integration Capabilities

You get the capabilities of integrating your smart warehouse solutions with existing ERP, WMS, and transportation management systems (TMS) for improved productivity. APIs and connectors ensure data exchange and synchronization between diverse array of systems for unified view of warehouse operations.

Mobile Accessibility

Mobile powered applications enable warehouse teams and staff to access critical information and perform important jobs from anywhere within the premises. Features including mobile scanning and voice-operated picking facilities improve warehouse productivity and accuracy.

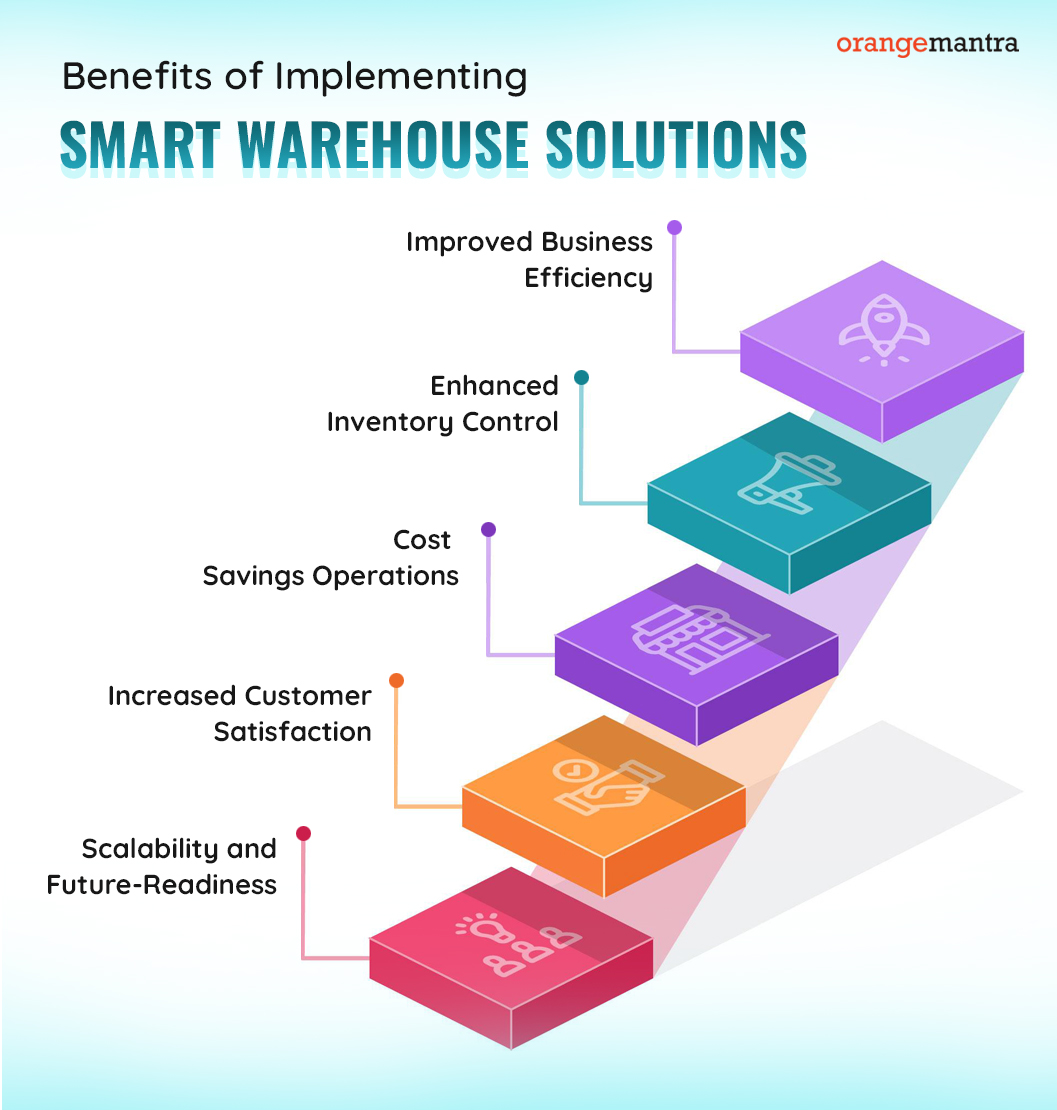

Benefits of Implementing Smart Warehouse Solutions

Improved Business Efficiency

Manual tasks are replaced with automation bringing workflow optimization and increased productivity. Streamlined processes lowered operational cycle, order processing times, and processing costs, leading to major surge in efficiency.

Enhanced Inventory Control

Tracking of inventory in real-time helps to minimize stockouts, overstock situations, and inventory mismatch. Automation within the Smart warehouse management system simplify data capture and barcode scanning process for accurate picking, packing, and shipping activities. If this process is simplified, you will experience reduction in errors and returns.

Cost Savings Operations

Reduced operational costs, revamped inventory process, and efficient allocation of resources results into cost savings. Better warehouse space management, and equipment maintenance results into higher operational efficiency and overall profitability.

Increased Customer Satisfaction

Customer satisfaction is another benefit of having Warehouse development services. You have faster order fulfillment, accurate order processing, and real-time order tracking to improve and personalize customer experience. Delivery on time, reduced lead times, and on-demand services results in improved customer satisfaction and loyalty.

Scalability and Future-Readiness

Smart warehouse system are easy to scale and even adapt solutions for business growth and changing customer demands. Continuous innovation and updates are an added advantage to keep warehouse solution agile, competitive, and future-proofed against market advancements.

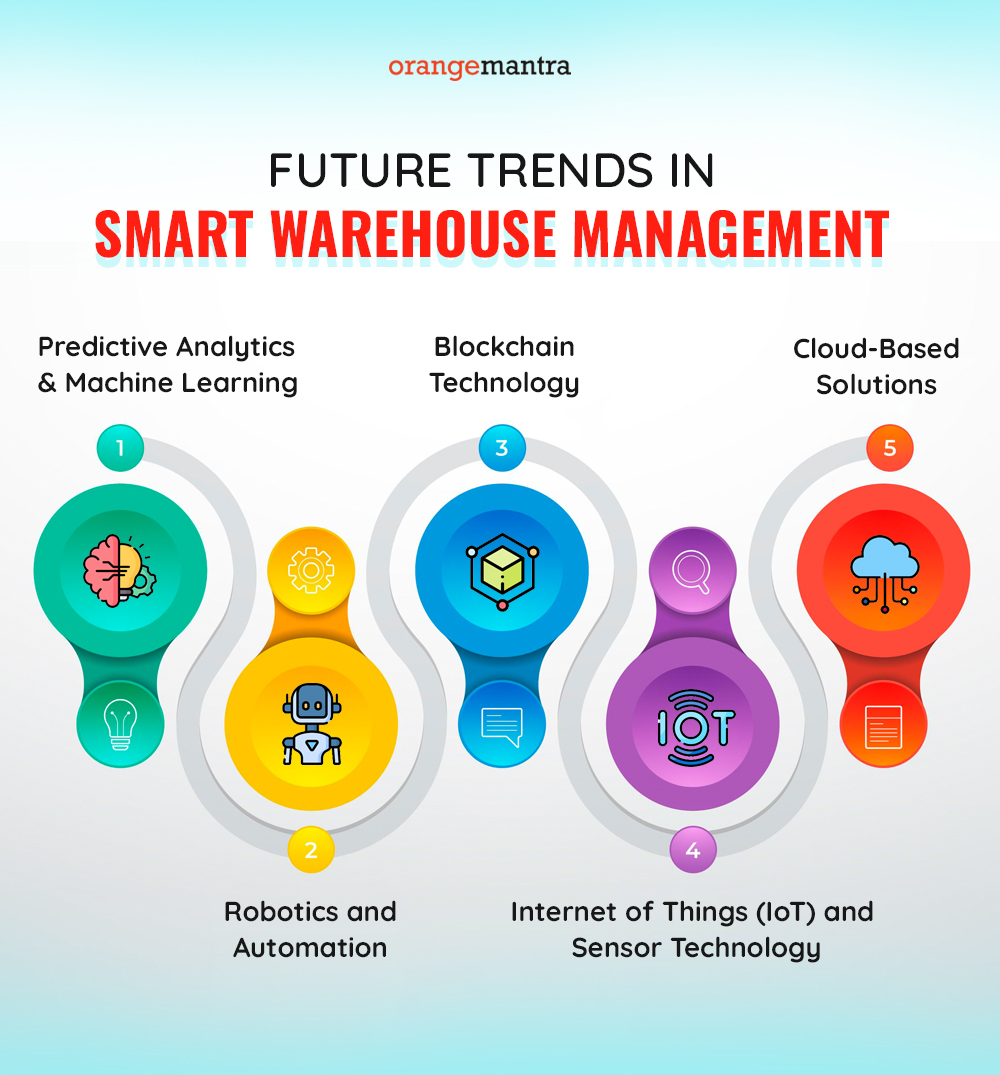

Future Trends in Smart Warehouse Management System

Predictive Analytics and Machine Learning

Predictive analytics and machine learning algorithms have a strong and long-lasting impact on warehouse management systems. Both operate by studying historical data, latest trends, and external factors to share demand patterns, inventory needs, and future challenges. Warehouses can adjust inventory levels, assign resources, and optimize workflows to maximize profitability.

Robotics and Automation

Another trend that you can integrate in your Warehouse is the RPA. This is highly beneficial to expand and keep operations sophisticated. Adding advanced robotic systems, including robotic arms and drones is a great advantage for doing complex jobs such as order picking, packing, and inventory management. Leveraging services of 3D printing enable faster, agile, and custom manufacturing processes.

Blockchain Technology

Blockchain technology add transparency, traceability, and security within the warehouse operations. The records of transactions, shipments, and inventory movements are protected from unauthorized access reducing the risk of fraud. Smart contracts can automate agreements, streamline processes including contract updates, payment transactions, and dispute resolution. Real-time visibility is present within the flow of goods across the entire supply chain operation.

Cloud-Based Solutions

Cloud computing in warehouse systems, offer greater flexibility, scalability, and accessibility. Store managers can have information access from any location with an internet connectivity, supporting remote management, real-time monitoring, and collaboration. Moreover, you can easily scale operations in response to changing demand, without significant investment in hardware or software.

Internet of Things (IoT) and Sensor Technology

The advancement of IoT devices and sensor technology will continue to improve warehouse infrastructure. IoT sensors within the warehouse collect real-time details including temperature, humidity, location, and motion. This data helps with environmental conditions, track movements, and detect possible issues in real time. Advanced analytics helps with making actionable decisions, optimize resource allocation, and improve decision-making.

Wrapping Up

Smart warehouse management software is a major transformation for modern warehouses looking to improve productivity, optimize operations, and stay competitive. By integrating advanced technologies like IoT, AI, Machine Learning, and other emerging technologies, you will get streamline processes, improve visibility, and drive innovation.

From real-time inventory management to predictive analytics, smart warehouse system offer improved efficiency, accurate operations, cost savings, and personalized customer services. By embracing these technologies, warehouses can achieve higher productivity, agility, and profitability, in the digital age.

As the demand for such solution is on the rise, it’s essential for businesses to connect a professional digital transformation company to adopt these technologies to remain competitive and future-ready. By consulting expert, your warehouse not only meet the demands of current market but also pave the way for a smarter and futuristic operations.

Frequently Asked Questions

1. What is smart warehouse management software?

Smart warehouse management software leverages advanced technologies including IoT, AI, machine learning, and automation to automate warehouse operations, including inventory management, and order fulfillment.

2. How implementing smart warehouse solutions is beneficial for my business?

Implementing smart warehouse solutions offers numerous benefits for your warehouse operations. It include improved efficiency, accuracy, cost savings, and customer satisfaction. Once you streamline processes, enhance visibility, and leverage automation, you get fruitful results for business success.

3. How my warehouse management improve predictive analytics and machine learning?

Predictive analytics and machine learning algorithms analyze data, current trends, and external factors to predict future demand patterns, inventory needs, and potential bottlenecks. By anticipating demand fluctuations and operational challenges, warehouses can optimize workflows, allocate resources, and meet customer demands effectively.

4. What role do robotics and automation have in warehouse management?

Robotics and automation automate repetitive jobs like order picking, packing, and sorting, reducing manual labor. Advanced robotic systems, including autonomous mobile robots and robotic arms, enhance productivity, safety, and flexibility in warehouse operations.

5. How can warehouses leverage cloud-based solutions?

Cloud-based offer greater flexibility, scalability, and accessibility, enabling warehouses to access software and data from any location. Scalable cloud infrastructure scale your operations up or down in response to changing demand, without investment in hardware or software.